We install the water heater ourselves. Required tools and materials. Do-it-yourself boiler installation - is it possible?

Hot water is one of the important components of the comfortable life of a modern person. Communal workers are responsible for its uninterrupted supply in cities, but what about those who are not connected to a centralized network?

There is only one way out - to purchase and install a water heater. Such devices are diverse, but as practice shows, electric storage models are in special demand among buyers.

The reason for having a one-way valve is that when there is a great need for hot water, draw cold water from the bottom of the tank in the opposite direction along the recirculation line, providing someone who finds rainfall in the icy moment.

Do not allow your consumption of hot water to increase your energy costs. The water heater is the third largest due to your home. Usually accounts for almost 13% of your energy bill. There are four ways to reduce the cost of a water heater: use less hot water, lower the temperature of the heater thermostat, insulate the heater, or buy a new, more efficient heater.

Installation of equipment is quite simple and will not cause special difficulties for the home master. And yet, let's take a look at how to install a storage electric water heater.

The device is a thermally insulated tank of arbitrary shape. A heater is mounted in it, which heats the water to the temperature set by the owner.

How to calculate the cross-section of the wiring to the electric heater

Tips for using a water heater. Quick re-enable cranes; for a short period of time there is a short-term discharge of water. Heat the electrical capacity of the storage tank, being careful not to block the thermostat. Follow manufacturer's recommendations. Heat the hot water tank with natural gas or fuel oil, but be careful not to block the top or bottom, or the thermostat or burner compartment. Follow manufacturer's recommendations; If you have any questions, seek professional help. Isolate the first 2 meters of hot and cold water connections connected to the water heater. Install heat traps on the heater’s hot and cold water connections to prevent heat loss. Some new water heaters already come with heat traps installed. The vapor portion of the contents of the tank every 3 months removes sediment, which prevents heat transfer and reduces the heating efficiency. Finding or searching for one to failure heater will help you choose the one that best suits your needs.

- Install low flow or pressure showers and taps.

- Take more showers than baths.

- Bathtubs use most of the hot water from the middle house.

Electric water heaters are a practical solution for the uninterrupted production of hot water. It is only important to correctly determine the volume of the device

It varies from 35 to 85C. In a thermally insulated container, the heated liquid maintains temperature for 2-3 hours. After the water cools down at 0.5 ° C, the automation is activated and the heater is turned on to warm the liquid.

Type # 1: Cumulative Pressure Equipment

Researchers have found that these tanks can save up to 30% compared to a conventional gas water heater. A solar heater will help us save gas because it heats water with energy from the sun. The system consists of two parts: a solar collector, which is responsible for capturing solar energy and a hot water tank in which hot water is stored. It is recommended to install a solar heater in series with a gas heater, to work as a backup in the winter or when we use a lot of water, for example, when we have visitors. Buy a new water heater that uses energy more efficiently. . At some point this will happen.

Upon reaching the set temperature, the device turns off. This mode of operation allows the device to save energy.

Heaters integrated in the tank may be tubular or spiral. The first option is more reliable, not afraid of air congestion, but eventually it is necessarily covered with scale.

Scale devices are not scary to spiral devices and they heat an order of magnitude faster. The tank may be steel or plastic. Its inner surface is coated with enamel or glass ceramics.

Your water heater will break. This is a “technical” term for plumbing, which means that your water heater stops working forever. Water heaters should be serviced periodically, but too often they are left to run without maintenance and, sacrificing themselves, give us hot water daily. When there were enough of them, they stop due to rust or corrosion.

The easiest and fastest way to replace a water heater is to make it a professional plumber, but if you cannot afford it, or if you really want to do it, read on. You must make sure that you follow the plumbing codes, so it is recommended that you contact your local plumbing inspector to find out what local requirements and permits and specific criteria exist. But replacing a water heater is not an extremely difficult task, and if you follow this guide, you will have hot water in a short time.

So that the welds of the steel tank do not rust, special anode rods are inserted into the tank, preventing the iron from oxidizing. They need to be changed with a frequency of 5-8 years.

The standard design of the water heater includes a thermostat, which is responsible for maintaining the set temperature. The control system of the device can be either manual or automated.

Connection of a storage water heater to a water supply system - scheme

Well, anyway, expect 4 to 6 hours. Choosing a new water heater. When choosing your new water heater, it is easiest to store the same type of fuel, whether gas or electric. In this guide, we assume that you will maintain the same type of fuel as the water heater you are replacing. However, you can resize it a bit. For example, let's say you have 150 liters and you want to go up to 190 liters. This should not be a problem if you have enough space between the heater and the wall.

The device can be equipped with an additional function of rapid heating of water. Storage water heaters differ in volume, which, in turn, affects the rate of heating water.

The larger the volume, the longer the equipment will warm up the liquid. It is advisable to accurately calculate the need for hot water so as not to make the device idle and not to lack it.

Preparing to install a water heater

Use the hand truck to move the new and existing heater up and down the stairs. Before you start, check the following points to make sure that you are ready to start when a new water heater arrives. Checking the pipelines Measure the distance between the centers between the hot and cold water pipes at the top of the water heater and try to make sure that the new heater is the same size. This will simplify the work of plumbing. Take a look at the piping connected to the old water heater.

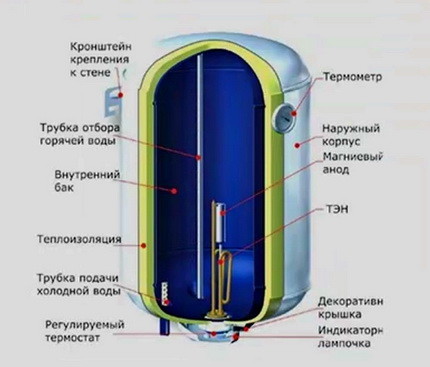

The diagram shows the general structure of an electric storage water heater

Types of storage water heaters

One of the most important criteria for choosing a device is its type according to the connection method. There are two types of such devices.

Necessary tools for installing the boiler yourself

Make sure you have a gas connection in the gas line, if you have a gas water heater, and make sure there is a valve to close the water for the cold water inlet pipe, and the hot water outlet pipe connector. But most plumbers do a good job of this task, so anything is possible on the spot.

Turn off the power and water in the water heater

Assembly Lowering the truck’s water heater and going down the stairs is a job for two people. After you lowered the new heater to the initial position of the heater, you are ready to start. Disconnect power and water to the water heater. Before you do anything, you must turn off the power and water to the existing water heater.

Type # 1: Cumulative Pressure Equipment

Used in systems where the water pressure is constant. At the same time, the type of water supply does not matter, it is important that the pressure is maintained in the line. Pressure devices have many advantages:

- Constant availability of hot water, since the device’s tank is never empty. As the heated water is consumed, cold water is poured into its place under pressure.

- Good water pressure. It is determined by the maximum pressure in the pipeline and is usually quite high, especially in comparison with the non-pressure analogue.

- Easy to connect to the mains. Given that the device has a power of 3-4 kW, there are no problems with the mains.

The equipment also has disadvantages. The most significant is the rapid decrease in temperature in the tank upon receipt of a large amount of cold water.

If you have a gas heater, close the gas in the gas supply pipe in the tank or in the main gas vent valve at home. To make sure that the gas is off, check the pilot’s flame; it must be turned off. Drain the hot water tank. When the water is closed to the heater, you will need to drain the tank.

Disconnect service lines

- Open the nearest hot water tap.

- Connect the hose to the drain valve on the water heater.

- Insert the other end of the hose through the floor drain.

- Slowly open the drain valve so that the residue does not close the drain valve.

The low power does not allow the heating element to quickly heat the water, so you have to wait until the device does its job. This drawback is especially noticeable in small-volume devices.

For example, a 50-liter tank when using a shower with a flow rate of 3-5 liters of water per minute after 15 minutes. will be filled with cold water. To continue the water procedures will have to wait a while.

Disconnect hot water, cold water and depending on the type of water heater, gas pipe or electrical equipment to the water heater. Remove and replace the water heater. Once the old water heater is completely discharged and disconnected, you can remove the old unit.

Ask an assistant to help you lift the old water heater into the truck of the machine and remove the old water heater. Move the new water heater to the position, aligning the pipes of the existing pipe sections in the water heater. Using a torpedo level or full level, level the new water heater by slowly raising or lowering your legs until the device is upright. Clean the floor on which the old water heater was installed. . Install new water heaters.

This disadvantage is offset by the correct choice of the volume of the device.

Type # 2: Non-pressure storage water heaters

The equipment is designed to work with pipelines in which there is no constant pressure. Water is supplied to the tank using a pump that starts manually or automatically.

Connect water pipes and gas or electric line

Then install the various accessories that come with the water heater. Use teflon tape at the ends of a copper pipe or connection in galvanized fittings.

- Install a pressure and temperature relief valve and empty the drain hose.

- Install any other fittings as directed by the manufacturer.

Connecting the water heater to the mains

If the inlet and outlet of the new water heater do not exactly match the old pipe, then use the flexible copper supply lines. Connect the power or gas line. After the water lines are installed, you are ready to install the fuel source.

In the latter case, a float switch is mounted inside the tank. Many consider the non-pressure system to be inconvenient and outdated, but in some cases its use is justified.

For example, the device will be very appropriate in a country house, the owners of which do not want to equip a full-fledged plumbing system. The advantages of non-pressure equipment include:

So he is sick of running out of hot water in the shower and wants to replace this old water heater. Or maybe you plan to use a lifeless heater for your new project. Well, water heaters without a tank are a great solution for the needs of hot water in a residential area. They are also called hot water heaters.

Because they usually do not store hot water, but create it when necessary. But even with all the talk about these devices, there are some limitations and concessions that must be taken into account before deciding whether or not a water heater is really waterproof for you. I have one in my house and, if used correctly, these gadgets are absolutely great. If they are not used correctly, they are disappointing and expensive. They are suitable for use with all versions of the house, as well as non-woven electric water heaters and models of natural gas or propane.

- Low power consumption, which allows you to install the device in houses with old wiring.

- Easy installation and connection.

- Slow mixing inside the tank of hot and new cold water.

Disadvantages of non-pressure water heaters are not very many. Among them is a low power, which makes it wait a long time until the water warms up to the desired temperature.

Some tankers are designed to heat one cup of tea, while others provide ample hot water for two or more bathrooms. In addition, the region of the country in which you live has much in common with how much hot water your water heater can create without a tank.

How a water heater works without tanks

Instant water heater without water. A tubeless water heater works by heating water directly at the time it is required. Unlike traditional water heaters that use a storage tank, non-tanks do not have a storage tank and therefore not.

In addition, you need to remember that the liquid enters the tank slowly. Therefore, the water level may drop below the minimum mark, and this will lead to the failure of the heater.

It is important to always keep track of this moment.

When choosing a place for a water heater, it is important to consider its type. Horizontal models should never be placed vertically, otherwise serious equipment damage cannot be avoided.

Residual heat loss is heat loss, and the energy used to heat the water is only for storage in the tank, and is typical for traditional water heaters. Avoiding residual heat loss is what makes water-free water heaters more energy efficient.

Regardless of whether you use a water heater without using a cylinder, as shown above, or the entire unit at home, they work the same way. Cold water enters the device and is heated by a heating element that burns with a flow switch. The heat exchanger may consist of electric resistance heating drums or a gas burner using natural gas or propane.

Choosing a place to install equipment

Before installing the device, select the place where it will be located. Accumulative water heaters are quite large in size, which must be taken into account when placing them. There are three types of devices:

- Wall-mounted, the capacity of which does not exceed 200 liters.

- Floor standing, from 200 to 1000 liters.

- Recessed, with different capacities.

In addition, there are devices of vertical and horizontal types. Depending on this type, the device should be located.

Incorrect placement complicates the operation of the equipment and quickly disables it. All these factors must be taken into account when choosing a place for a water heater.

In addition, a number of requirements must be fulfilled. The device must be mounted in a place protected from the cold so that the water does not freeze. It should be located close to the water outlets.

In this case, it is desirable that the length of the water pipes is minimal.

To install a massive floor storage water heater, you need a solid, even base, in some cases it can be a special stand

If the water pipes are too distant from each other, it is worth considering the installation of several water heaters. It is desirable to choose a place for the device so that pipelines with cold and hot water are located close enough and are easily accessible.

It is also important to examine the status of the wiring. Particular attention should be paid to its cross section and the ability to withstand additional power. If necessary, the wiring will have to be replaced.

Another important issue is the availability of equipment. There should be enough space at the installation site for unhindered installation work, subsequent maintenance and possible dismantling.

Based on this, it is necessary to provide a free distance from the nearest surface to the protective cover of the device. It can not be less than 50 cm.

If a water heater is planned to be installed in a bathroom, it must be taken into account that there are zones with different humidity levels. In some of them, the installation of electrical equipment is strictly prohibited.

When attaching wall-mounted devices, it is very important to determine the strength of the wall. Brick and concrete partitions, even if ventilation shafts pass behind them, can withstand the device up to 100 liters. Equipment up to 200 liters can only be hung on load-bearing walls.

If there are serious doubts about the strength of the wall, do not hang on it a device with a capacity of more than 50 liters. In this case, you will have to install a special supporting frame made of metal.

The place for built-in water heaters is chosen in strict accordance with the recommendations of the manufacturers.

After the place for equipment is selected, you can proceed with its installation.

Fixture

The easiest way to install a floor heater. Most often, this is a massive device that is placed directly on the floor or on a small stand.

The main condition is that the base is strong and even enough, since the equipment should be without distortions. With wall mounts, things are a bit different.

Vertical heaters up to 100 l are usually hung on two supports. For larger devices and horizontal models, four mounting points are provided.

The mounting scheme for water heaters varies. As fasteners, you can use concrete anchors, dowels with screws or L-shaped wood screws.

Wall-mounted storage water heaters are usually equipped with a special mounting bracket, with the help of which the device is securely fixed to the wall

It is important to choose the right fittings so that they fit the wall material. A special mounting bracket may be included with the device.

We perform the following operations:

- Mark the wall. If the device is fixed to the bar, apply it to the wall, check the horizontal and mark the places under the fasteners.

- Cooking holes. With a hammer drill or punch, we make holes and insert fasteners into them.

- We attach the device and securely fix it.

If the model of the water heater does not provide for the mounting bracket, the housing is equipped with brackets with eyes.

In this case, you must especially carefully mark the fasteners, because in case of an error, the eyes simply will not fall on the hooks.

The heater should be installed in strict accordance with its design, so that all horizontal and vertical nozzles are located exactly as recommended by the manufacturer.

In addition, the hooks on the wall must be installed so that spontaneous movement of the device along the wall is completely eliminated.

General scheme for installing an electric storage water heater

Water connection

The manufacturer affixes a mark on the heater tank indicating the connection points for hot and cold water. They are indicated in red and blue.

When connecting the device to pipelines, stopcocks and a back-safety valve on the pipe with cold water should be installed on both lines.

Cranes are needed to shut down equipment in the event of its periodic use or for maintenance and repair during continuous operation.

The non-return valve is placed at the inlet to the water heater. It is designed to protect the device from overheating or overpressure. In addition, when the cold water supply is interrupted, it will prevent it from flowing out of the boiler.

- We connect the device to the pipeline with cold water. To do this, we need to screw a tee on the inlet pipe of the tank. Do not forget about the sealing tape-fum or tow with silicone.

- We install a tap on the side of the tee, which will work as an emergency drain. Experts recommend that you mount this part, since the regular drain hole of the heater is often very small and the drain procedure can take several hours.

- On the bottom of the tee we put a back-safety valve.

- In the lower part of the structure we mount a shut-off or shut-off valve.

- We install a threaded adapter and with it we connect the cold pipeline to the boiler.

- We connect hot water. First, install the stopcock.

- We connect the tank to the pipeline by means of a threaded adapter.

Accumulative non-pressure water heaters are recommended to be connected according to this scheme

The above general diagram is intended for connecting pressure models. If installation of a non-pressure device is carried out, we act a little differently.

In this case, we will connect the device to the auxiliary capacity, which is used as a drive. It must be installed at a height of at least 2 m from the top of the heater.

Moreover, if the pressure in the water supply exceeds 6 bar, it is necessary to install a pressure reducer in front of the water heater, which will reduce the overpressure.

Mains connection

The storage water heater is a fairly powerful electrical appliance, for the operation of which it is necessary to equip a separate splash-proof high-quality outlet. It should be located in the most protected from moisture place and have a ground terminal.

The supply line should be equipped with an RCD (residual current device) and a circuit breaker that protects the network from overload currents in the heater and possible short circuits.

The nominal value of the device is 16 A. The installation of an RCD is necessary to protect the user from possible electric shock from a water heater.

So in reality the correct connection of the storage water heater to the water pipes looks like

The device can be installed in the shield or in the form of an adapter. At the same time, the rating of leakage currents cannot be more than 30 mA with a minimum load of 16 A.

If you wish, you can hold a separate cable to the boiler, it will go directly from the meter. Before starting work, you need to soberly assess your strength. Working with electrical wiring requires certain knowledge and skills.

Errors during installation threaten with electric shock and equipment failure. If there is no experience with electricity, it is better to seek help from specialists.

Preparation for operation

To prepare the water heater for operation, it is necessary to remove the air accumulated in it from the secondary circuit, otherwise, when heated, air bubbles will move along the coolant and cause unpleasant noise.

To do this, fill the water circuit with water to failure. In this case, until the tank is full, the hot water tap remains open.

Upon completion of installation work and connecting the device, we once again check the quality of the connections of all nodes and conduct a test run of the device

A storage electric heater is a practical solution for providing home with hot water. Different types of devices can be connected both to a water supply system and to a storage tank with water or a pump.

Installation of equipment can be carried out independently, especially if the home foreman has experience in plumbing. It is important to strictly follow the manufacturer's instructions and correctly install and connect the heater.

Only then will the device serve its owner for a long time and without interruption.

Hot water supply of the apartment is one of the main components of a comfortable stay in it. The vast majority of city dwellers can’t even imagine what could be otherwise. But the problem is that far from all residential buildings have hot water supply. In addition, even from residents of fully-equipped apartments, one can often hear complaints about the "quirks" of communal services associated with frequent interruptions in the supply of hot water and unreasonable price increases for pay for this service.

The best solution is to achieve autonomy in this matter, to have your own water heater at home, and best of all, the accumulative principle of action, a boiler, so that the supply of hot water is always at hand. But how to choose a boiler in an apartment so that it fully meets the expectations of the owners? And the second problem is how to install a boiler in an apartment so that it works correctly and does not pose any danger to residents? Answers to these questions will be given in this publication.

First of all, it is necessary to navigate in the variety of storage water heaters, since there are many of them, but not everyone can approach the conditions of a particular apartment.

First of all, boilers are divided into devices of direct or indirect heating.

1. Indirect heating water heaters do not use energy in the form of electricity, gas, solid or liquid fuels. Water used for domestic use ( her often called sanitary) heats up due to heat exchange from passing inside the circuit, connected to the heating system (sometimes other sources of hot water are also used, for example, circuits, connected to solar heat accumulators).

The figure shows a schematic diagram of such a water heater.

- Cold sanitary water enters the boiler tank (2) through the tube (8).

- Hot boiler industrial water circulates through the heat exchanger (6), which gives its heat to the sanitary. There can be several heat exchangers, they can be in the form of coils (as in the figure) or are arranged on the principle of "tank in tank".

- Through the pipe (11) is the intake of heated sanitary water.

- The entire boiler is enclosed in an enameled steel casing (4), and the space between it and the inner tank is filled with a powerful layer of thermal insulator - polystyrene foam (5), which ensures the preservation of the heat of heated water.

- A magnesium anode (10) is installed inside the tank, which is intended to prevent the buildup of scale on the walls of the vessel - it “pulls” it onto itself due to the lower electric potential, and is subject to regular replacement as it grows.

- An electronic control unit (1) with a temperature sensor (3) ensures that the required temperature of sanitary water is maintained. Since the boiler itself does not use its own heaters, the control is through the adjustment of the circulation flow of process water coming from the boiler.

Indirect heating boilers are economical and high performance, of course, with sufficient power of the main boiler. However, they are not suitable for the conditions of the apartment. The fact is that nobody will probably allow connecting such a water heater to the central heating system - this will lead to a significant drop in temperature in the heating circuit. In addition, for six months this device will essentially stand idle without an external heat source. Even if an autonomous heating system is installed in the apartment, all the same, such a choice will not be optimal. The boiler itself requires considerable space, and in cramped apartment conditions it is easier to immediately install a dual-circuit boiler.

2. In direct heating boilers, the principle is different - the transfer of thermal energy goes directly to sanitary water from an energy carrier - natural gas, electricity, solid or liquid fuel. In apartment conditions, of course, either gas or electric storage water heaters are used.

2— 1. Gas storage boilers, which should not be confused with geysers, which are instantaneous water heaters.

- The water in the tank is heated from a gas burner (4) located below, under a panel of a special spherical shape, and from a pipe for the removal of combustion products passing through the tank.

- The thermostat system (3) monitors the heating level, controls the gas supply valves and the piezoelectric ignition device. As soon as the temperature of the water drops below the set value, the gas burners turn on.

- There is also a magnesium anode (5), the function of which is mentioned above.

Such boilers are much more economical than electric ones, they are characterized by high performance, but they are not very popular among apartment owners, which is explained by a number of reasons. Firstly, they definitely need a system for removing burnt gases, in the form of a “classic” or coaxial chimney. Secondly, the installation of such a water heater will require mandatory coordination with the gas supplying organization and the state technical supervision authorities. And thirdly, the cost of such boilers is significantly higher than the most common and popular among residents apartments - electric.

2— 2. Electric boilers are widely used in urban multi-storey buildings. They are quite compact, which allows them to be placed even on a small area, quite easy to install, which does not require any coordination, are simple to operate, reliable and quite economical.

Exists a great many different models, but the basic scheme for all is approximately the same:

- The outer decorative casing (1) and the inner tank (3), the space between which (2) is filled with peat-insulating material (polyurethane foam).

- Cold water inlet (4) with flow diffuser (5).

- Hot water intake pipe (9) from the top of the boiler.

- The heating element is a heater (7), the design of which may be different.

- Magnesium Anode (6).

- A temperature sensor (8) associated with the electronic circuit of the thermostat, which controls the on and off supply voltage of the heating element to maintain a predetermined water temperature in the boiler.

As you can see, the circuit is quite simple and reliable. The cost of such boilers is quite affordable, which leads to their highest popularity among other storage water heaters. A further description of the selection and installation of water heaters will be devoted to this particular type of water heater.

3. For completeness, it is worth mentioning another type of accumulative boilers - combined.

They combine the functions of both indirect and direct heating. For example, the diagram shows such a boiler:

There are two containers in the case. In the outside, the process water circulates from the heating circuit. The inner tank (9) of stainless steel serves as a battery of heated sanitary water. It contains an electric heater and a thermal sensor. If the capacity of the external boiler is not enough to reach the set water temperature, the electronic system turns on electric heating. It is clear that during the period when the boiler is not in use ( at the end heating season) electrical heating becomes basic.

Such boilers, although they combine all the positive qualities of indirect and direct heating water heaters, are still very expensive, and for apartment conditions their use will be irrational.

How to choose a boiler in the apartment - practical tips

So, if a decision is made to purchase and install an electric storage boiler, you should know what parameters should be considered when choosing it:

1. The required volume of the storage tank.The variety in this matter is large, and it is necessary to select the optimal model so that the needs for hot water are fully provided for all family members, and at the same time, there is no need to overpay for absolutely unclaimed volume and power consumption.

With a preliminary "estimate" proceed from the following parameters:

- The number and type of taps connected to the hot water circuit.

- The number of people living in the apartment.

Usually, for a boiler, the temperature of heating water to 60 ° C is considered optimal. However, this is very hot water, which must be mixed with cold during use. For the convenience of calculations, you can tabulate the average water flow rate for certain procedures in a table and translate it into a 60-degree one:

Based on these data, it will be easy to calculate how much boiler is needed so that all family members can take water procedures one by one without waiting for additional heating of the water. It is clear that when you take a bath you won’t be especially “run up”;

For even more ease of selection, a table will be given that summarizes the recommendations for the required volume of the water heater, based on the number of residents and the type of water points:

2. Power consumption.The higher it is, the faster the water will heat up. However, do not forget that excess power is also not needed, since such a boiler will seriously load the wiring in the apartment. Usually for an average water heater 2 - 2.5 kW is enough. Nevertheless, although a regular power outlet (its standard threshold is 3.5 kW) must cope with such power, it is strongly recommended that you install a water heater with a separate power line from the distribution panel. In addition, if its power is above 3 kW, it is better to do without sockets, installing in the immediate vicinity of the boiler a circuit breaker for 16 - 25 A.

3. Dimensions and housing option.It is clear that these parameters mainly depend on the selected volume of the boiler, but here there may be some peculiarities.

The most common for most users are vertical water heaters. They are the most productive and economical, differ in low cost.

"Classic" type - vertical cylinder

Previously, the main form of the boiler was a cylinder. Such water heaters are easy to install and maintain, but they protrude excessively along the front, which sometimes prevents them from being installed in a cramped room.

“Flat” boiler takes up less free space

More compact are the boilers of the “flat”, flattened from two edges of the form. This layout of the tank, of course, is smaller, but it also has drawbacks - it is much more expensive and has many welds that can reduce the overall strength of the structure and increase the area of \u200b\u200bpossible corrosion.

Recently, horizontal-mounted boilers are becoming more popular - if the width of the wall allows, they are often chosen. They are distinguished by rapid heating. Their only drawback is that such a layout does not allow to achieve high performance.

"Flat" horizontal water heater

Horizontal boilers can also have a cylindrical or “flat” shape.

Most household boilers are designed for hanging on the wall. Large volume boilers can be in the floor, but they take up a lot of precious space.

An important note - it is not allowed to independently change the orientation of the boiler - the vertical and horizontal models have their own design features, and they can only work correctly in the normal position.

4. The inner coating of the water tank can also vary significantly.

Enamel tanks are the most inexpensive, but an anode rod must be installed in them to collect scale. The disadvantage can be considered the instability of the enamel to large temperature differences - in case of accidental overheating, such a coating may crack.

Boilers with stainless tanks are more practical - they are not afraid of the increased hardness of the water and the excessive concentration of chlorine-containing components in it. Some water heaters with tanks of their high-quality stainless steel are not even equipped with anode rods due to their uselessness. Stainless steel tolerates elevated temperature and pressure, without giving deformation. Of course, the cost of such models is already much higher.

Modern, innovative solutions are expensive but very reliable boilers with glass-porcelain-coated tanks. Such containers are absolutely not afraid of corrosive effects, are completely chemically inert, are not susceptible to cracking or peeling, which, for example, are enameled. Glass-porcelain cover is the most environmentally friendly - the water will never have an unpleasant odor or taste, it has an antibacterial effect. All these advantages, of course, affect the cost of such models.

5. Existence of protection against a scum and corrosion,which was mentioned above.

You can add here that some models are equipped not with magnesium, but with inert anode rods, which are much more efficient and require frequent replacements. True, this convenience also affects the cost of the boiler.

6. Type of electric heater. You can choose a boiler with a "dry" or "wet" heater.

"Wet" heater is in direct contact with water

The usual “wet” heater is in direct contact with the heated water, which gives it greater efficiency, but, at the same time, increases its vulnerability to corrosion and scale deposition.

"Dry" heater is installed in a sealed capsule

“Dry” heating elements are enclosed in an airtight capsule and have no contact with the liquid. They are more durable, they are easier to change in case of failure. The only negative - these advantages are reflected in the cost of the entire boiler.

7. Type of display and control unit. Low-cost models have dial thermometers and mechanical thermostats. More modern water heaters can have a block with a digital display, a touch control panel. It is difficult to give advice in this matter - everyone chooses according to their preference and financial capabilities. I must say that there are models even with remote controls - this is especially convenient for horizontal-mounted boilers installed high from the floor surface, under the ceiling.

8. Manufacturer and external design of the water heater.Of course, preference should be given to the original models of famous brands. There are many products of Turkish or Italian assembly on sale, which, while remaining, in principle, of high enough quality, are nevertheless equipped with inexpensive parts (internal containers, control units and heating elements) made in China. The total duration of their trouble-free operation sometimes causes some doubts.

In this regard, German manufacturers using their own components stand out for the better. They are often quite large, due to the impressive thermal insulation layer, but this is justified by the fact that the daily decrease in the temperature of fully heated water in a boiler disconnected from the power supply does not exceed 5 - 7 degrees.

Although most boilers are not distinguished by their bizarre forms, their decorativeness is still achieved by the external design and the variety of hues of the body color - it is possible to choose the most suitable option for the chosen room style.

independently

Services for the installation of boilers in the apartment are provided by many service organizations and private craftsmen. However, it is possible to carry out the installation of a water heater on its own, if there are basic skills in working with plumbing and household electrical equipment.

Actually, the whole installation process can be divided into three main stages: suspending the boiler in the place intended for it, inserting it into the home water supply network and connecting to the power supply.

Mounting preparation and boiler suspension

To begin with, you should once again evaluate the condition of the wall on which the boiler will be suspended - it must reliably hold fasteners under heavy load. It is strictly forbidden to suspend a boiler from a drywall wall if no additional reinforcing structures are used.

The place of suspension of the boiler should provide free access to it and visual control of the indicator panel and the general condition of the device.

At the same time, the water heater should not be too far away from the points of drawing. In the case when, for example, the kitchen and the bathroom are very separated (this happens in some series of houses), the best solution is to install two boilers - one, a small volume, for kitchen needs, and the second - for water procedures.

The minimum distance from the top of the boiler from the ceiling is 100 mm. From below, this value should not be less than 500 mm.

Usually, special water heaters come with a water heater. hook dowels the required diameter and length, designed for a double load (so, with a boiler volume of 100 l, the fasteners must withstand 200 kg). If there are no fasteners in the kit, it is necessary to purchase hooks with a length of at least 100 - 120 mm, a diameter of 8 mm, and an external diameter of the dowel - 12 mm.

At the installation site, it is recommended to plumb off the vertical center line, from which further marking will go. Then, at the desired height, taking into account the dimensions of the boiler, symmetrical holes are marked corresponding to the location of the hooks on the mounting plate welded to the body of the water heater. The horizontal layout is controlled by the building level.

Using a hammer drill, holes are drilled into which plastic dowels or metal anchors with hooks are driven. The hooks are screwed so that they enter 5-7 mm above the surface of the wall.

After checking the reliability of attachment, you can hang the boiler on hooks.

Some boiler models have a special suspension system. Their kit includes special brackets that are mounted to the wall using hex dowels with a wrench. The shape of the standard brackets is consistent with the mounting plate of the water heater, and it will not be difficult to suspend such a boiler. A special template, sometimes supplied with the product’s technical documentation, can be especially convenient — this will greatly simplify the process of marking holes.

Connecting the boiler to cold and hot water pipes

The next important task is to crash into the pipes of cold and hot water supply. An approximate general connection diagram is shown in the figure:

Installation of tees will be required if free branch pipes for these purposes were not foreseen in the water supply system. Before tees on both pipes, it is recommended to provide shut-off valves (on a hot pipe, when connecting the apartment to the central hot water supply, a shut-off valve is mandatory - it is closed in case of switching to an autonomous water heating).

How can I insert?

If the pipes are metal-plastic or polypropylene, then there are not many problems - a standard tee is installed, which is mounted on compression fittings or soldered using a special apparatus. From these tees, pipes are routed to the location of the boiler.

More problems will be created by a metal pipe in a long integral section.

Tee clip is not the best option

Some masters practice drilling a pipe body with the installation of a clamp-type tee-clip. However, there are many more opponents of this approach - such an insert is not very reliable, and, in addition, there is a high probability of clogging of the pipe in this place.

Sgon with an American nut

It will be much more reliable to cut a pipe section and cut the threads on both pipes formed using a die of the corresponding diameter. After that, it will be possible to install a metal tee on a flange or, even better, on a system of union nuts - “American women”.

If the filter sump is not installed in the water supply system, then it does not interfere with its installation - it will prevent clogging of the boiler capacity with solid inclusions.

Often the pressure in the water supply network is not stable, but for the operation of the boiler it is not entirely useful. In order to equalize the inlet pressure to the water heater, it is possible to install a pressure reducing valve of the required rating (usually, about 2 atmospheres).

In the immediate vicinity of the boiler, it is recommended to install another pair of shutoff valves - this will facilitate the process of dismantling the device if it is necessary to remove it for repair or maintenance work.

All metal threaded connections are carefully “packed” with tow or a special fum tape.

Now about how to connect the pipes directly to the boiler itself.

The boiler nozzle, marked in red, is connected directly to the failed hot water pipe. Often use flexible hoses for this. This is quite acceptable, but the hoses themselves must be of very high quality so that no vulnerability is formed in this area. Experienced craftsmen always strongly recommend connecting with polypropylene pipes with American nuts.

But connecting to a cold pipe requires a special approach, so it is worth considering in more detail.

The importance of the safety valve

This small in size, rather uncomplicated in its design device plays a key role in ensuring the safe operation of a water heater.

Mandatory cold water pipe connection - safety valve

Typically, such a valve is a structure of two cylinders located perpendicular to each other.

- In the cylinder with a threaded part there is a poppet check valve that does not allow the outflow of water from the boiler to the cold line when the pressure in it decreases.

- In another, there is also a poppet valve, but with a more powerful spring, which is triggered when the pressure in the boiler is exceeded the maximum permissible value. This opens the drainage pipe through which excess fluid is discharged, thereby equalizing the pressure in the water heater. A handle can also be located on it to force the valve to open - it can be useful for draining water from the tank during maintenance work.

To more clearly explain the importance of this device, it is better to consider a few examples:

- The absence of a check valve may lead to the following situation. When water is heated in the boiler, the pressure in it increases. Sooner or later, the moment is created when it exceeds the pressure in the cold pipe and the reverse flow of already heated water flows through it - it may appear when the “cold” tap of the mixer is opened or it may end up in the toilet bowl.

- Even worse, if for some reason the pressure in the cold water supply system disappears altogether (for example, repairs are carried out on the main). Hot water from the boiler will simply go into the pipe, and the heater will heat the empty tank, which will lead to the failure of the heater and to cracking the enamel. Of course, this should prevent the system from automatically turning off the power when overheating, but you can not rely on it only.

- However, the installation of a conventional non-return valve does not at all solve the entire safety problem. On the contrary, if you install only it, you can cause disastrous consequences - and after all such "craftsmen" are still found! The banal failure of the thermostat in this case creates an explosive situation. The temperature in the tank rises, the pressure rises, but in a closed volume the water does not boil. But if only an exit appears - a crack in the tank or a tap opened by someone, a drop in pressure will lead to instant boiling of water with huge vaporization and a powerful explosion.

Consequences of neglecting safety measures - exploded boiler

So, all this can be avoided by installing a safety valve. It is screwed directly into the boiler pipe, 3–4 turns with the usual plumbing “packing”. And only then can the water pipe be connected to its other end with a flexible hose or in any other chosen way. There is always an arrow on the valve showing the direction of the water flow - this should be checked during its installation.

A thin flexible hose can be connected to the outlet drain pipe of the valve with its outlet to the sewer. It is recommended that this hose be transparent - for visual monitoring of the operation of the device.

Under no circumstances should any shut-off valves be installed between the safety valve and the water heater - and that’s enough common an error, judging by the photos posted on the Internet.

When the boiler is operating, one should not be afraid that sometimes water comes out of the valve branch pipe - this only indicates its normal functionality. If too much water flows out - the spring may have hooked, and the valve should be replaced - they are sold freely. The alarm should be caused by a constantly dry valve - has it not broken, is it jammed or clogged? To protect yourself in such a situation, it is worth checking it and, if necessary, replacing it.

Some models of boilers are equipped with a “safety group” - a pressure reducer, a non-return valve, and a safety valve are assembled in one housing. Such devices are installed in a similar way - at the inlet of cold water.

Connecting the boiler to the mains

This issue has already been partially discussed above, so it can be discussed briefly.

- As a rule, boilers come with an already installed power cable and a three-pin plug to ensure connection to the grounding circuit - this will prevent electrical injury in the event of a phase breakdown on the device body. Accordingly, the socket installed near the water heater must have a grounding contact.

- You can find boiler models that do not include a power cable. In this case, you will have to purchase it and connect it to the terminal block yourself. The color coding of the wires must be taken into account: blue - zero (N), brown, red, gray or black -, phase (L), and green-yellow - ground loop (PE). The plug must be rated for a current of at least 16 A.

Test heater start

Once everything is ready, you can test the operation of the water heater.

- The correctness and tightness of the pipe connection is checked again. It is controlled that the valve on the hot water line is closed.

- The boiler is filled to the top with the “hot” tap on the mixer open - until water starts running from there. After that, the mixer is closed.

- Some models have a special manual valve for initial filling - this will be indicated in their instructions.

- The water heater is connected to the mains, the required temperature is set on the thermostat. In working condition, the indicator on the boiler lights up.

- It remains to monitor the rise in water temperature and the operation of the thermostat when it reaches its specified parameter.

- And, of course, during the initial start-up, you should make sure that there are no leaks on the joints of the pipes or flexible hoses.